Energy Cover Crops

An energy cover crop is a crop planted and harvested between two main crops in a crop rotation.

Byproducts from the Agri-Food Industry

The agri-food industry generates various materials during production. When these materials are used for anything other than a final product, they are called “byproducts,” such as apple pulp, downgraded fruits and vegetables, recipe mistakes, eggshells, and more.

Animal Byproducts

The use of animal waste is subject to European regulation (EC No. 1069/2009) to maintain a high level of hygiene. This regulation requires specific pre-treatments for different types of animal waste before methanization.

Main Crops

These are crops primarily grown for energy production. Their use in methanization units is strictly regulated to avoid competition between energy production and food supply.

Household Organic Waste and Similar

This refers to waste from households, municipal services, sanitation waste, and street cleaning waste.

Green Waste

Green waste refers to plant material resulting from the maintenance and renewal of green spaces (parks, gardens, sports fields, etc.) from local authorities, public and semi-public organizations, private companies, and individuals.

Sludge

This includes sludge treated in urban wastewater treatment plants, as well as sludge from the agri-food industry, which is liquid waste from slaughterhouses, dairies, cheese factories, bakeries, breweries, canneries, and more.

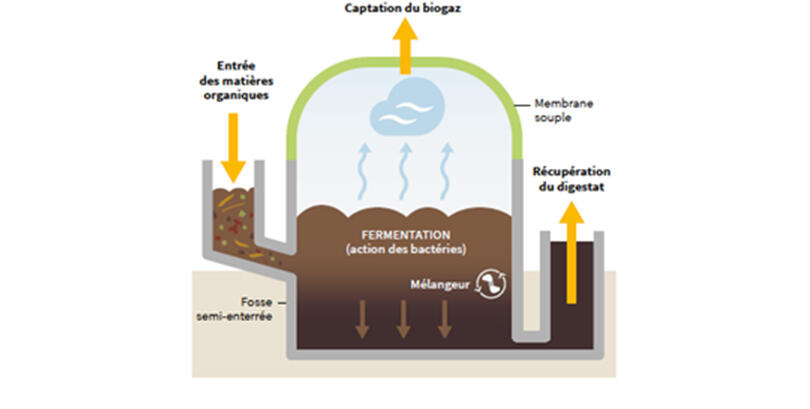

Depending on the type of input, the methanization process may vary significantly, especially regarding the moisture level of the organic matter, such as in wastewater treatment plant sludge (WWTP); this is known as non-WWTP methanization or WWTP methanization.

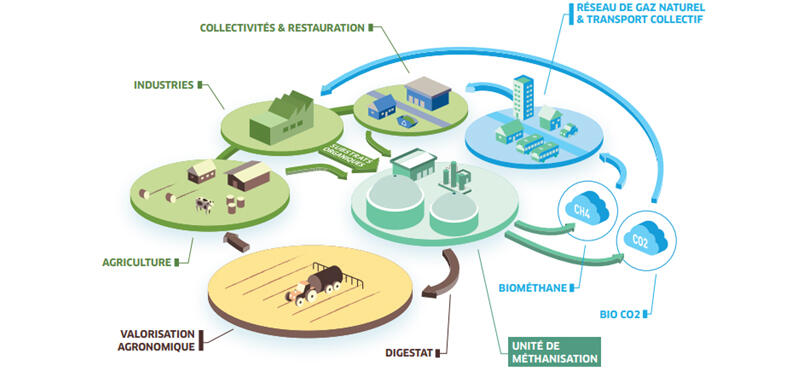

The Methanization Cycle